Soil drilling

The execution

- During drilling, PID measurements can be executed for the detection, localisation and qualitative measurement in the drilling process of volatile compounds. Other comparable measurements (such as oil-water reaction, ...) are part of the possibilities.

- Each drilling team has the latest and most accurate equipment for measuring the locations of the drill points, or for positioning predetermined drilling locations.

- The drilling data of a soil drilling is recorded by the drilling team via a handheld computer.

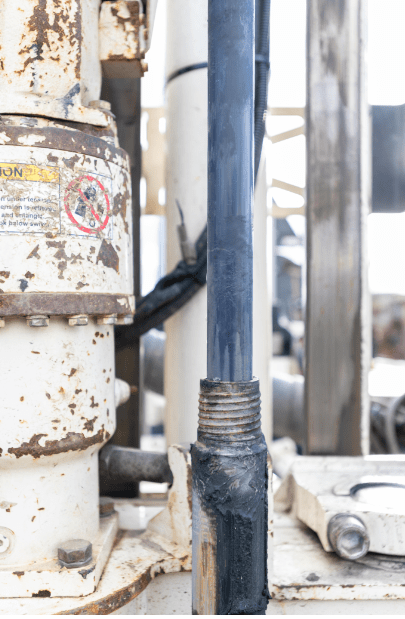

- All drilling equipment is thoroughly cleaned between the various soil drillings and is checked and cleaned with a high-pressure lance every night.

- The drilling teams are mainly deployed for environmental hygienic soil surveys, but can also be deployed for recognition drilling and placing monitoring observation wells around construction works.

- The manual teams are fully equipped with the equipment needed for the execution of well drilling and soil drilling in various soil types. In addition to the classic drills (Edelman, Clay, Grind, ...), they also always have the equipment to place ground bores through pulses with work water (borehole tubes and pulse) and to eventually pierce any hard surfaces (core drill) and rubble (ramguts).

- Depending on the capacity and the technique of their drilling machine, the machine-operated teams are assigned according to the requirements of the site where the soil drilling must be executed. This is largely determined by the geology of the site that is to be surveyed, the purpose of the soil drilling (taking soil samples with monitoring well placement, single monitoring well placement, ...) and the size and depth of the borehole. Envirosoil has 5 drilling machines, 3 of which with direct push dual tube technology combined with full and hollow auger technology. In addition, we have 1 machine with casing and pulse technology, combined with direct push dual tube, respectively full and hollow auger technology and 1 machine with full and hollow auger and rotary well sinking machinery technology. The different machines have various accessories through which specific techniques can be applied, as well as being able to drill under various conditions, such as from on a pontoon to a reasonable depth below the waterline.

Governments, owners and potential buyers of land can use our drilling teams to get a clear view of the structure of the soil. Our specialists provide a clear description of the soil composition in this regard. Contact them for more information.

Envirosoil has a VCA* certificate.